Different as traditional toilets relying on their own gravity as the power source, vacuum toilets use negative pressure to be power source. The pipeline installation process can follow the structure’s exterior, interior linear, curved, and even upward and downward directions. It is truly realize to “the water flows upward”

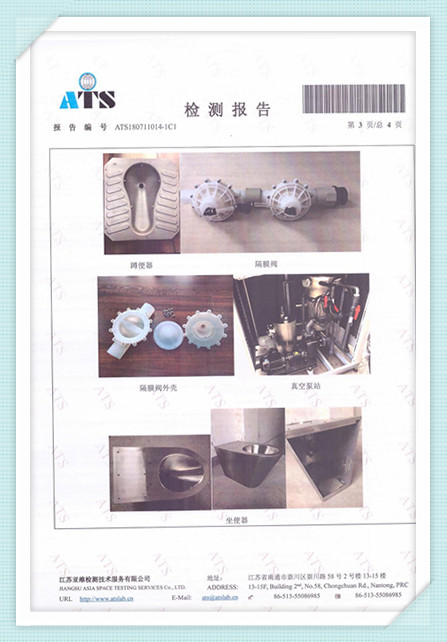

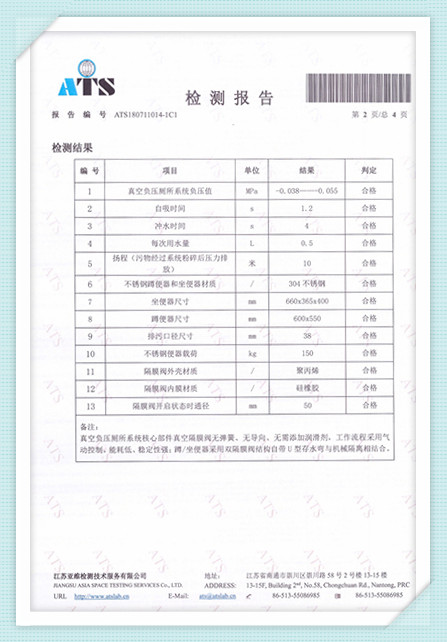

Compared with the traditional toilet with different gravity drainage methods, the vacuum toilet uses a negative pressure source of -0.035MPA to -0.055mpa to ensure that there is enough power to transport the raw water, and is equipped with a crushing mechanism to reduce blockage and pipeline pollution is small amount, so not easy to freeze.

The pipes are in a vacuum-sealed condition, so odors can not diffuse, and there will be no harmful gases and germs in the pipes.

Little water consumption of vacuum toilets directly reduces black water discharge, reduces the burden of municipal black water treatment, and solves the problem of black water directly discharged from natural water in modern society and pollutes water sources problem; vacuum toilets collect sewage concentrated, plus collected pollution with a high concentration of substances, which can make organic fertilizers used in organic agriculture. This can truly turn waste into treasure and achieve zero emissions. It solves the problem of material recycling for environment, also in agriculture recycling.

| Size | Length | Width | Height |

| 4920mm—-9600mm | 2200mm | 2600mm |

◎The interior is equipped with an emergency alarm system, clothes hook, hand box, hand dryer, sensor plus manual flushing switch.

◎The main structure adopts high-quality light steel keel welding as a one-piece structure, the base is 20# channel steel, the main frame is 120×100 square tube welding, the secondary frame is 80×40 and 50×50 square tube welding, all frames are treated with anticorrosion treatment, steel Anti-corrosion treatment at the welded parts of the frame steel components is durable and the wall thickness is above 2mm.

◎The inner wall adopts high-grade inner wall carved board, and the outer wall adopts a combination of aluminum-plastic board and steel metal paint. It has the characteristics of beautiful appearance, corrosion resistance, acid and alkali resistance, impact resistance, fire prevention, and long life.

◎High-grade non-slip ceramic tiles are used on the toilet floor.

◎The roof is laid flat and waterproof and insulated to ensure the complete and beautiful roof structure.

◎The ceiling of the toilet is made of ecological wood ceiling, and the toilet is generous and beautiful as a whole.

◎The management room is equipped with a general distribution box, power switch, socket, daylighting window, integrated vacuum base station (for sound insulation treatment), clean water tank and dirt box, which can meet the needs of 2000 to 3000 people in an environment with no water inflow and no sewage. Customers can choose heating and heat preservation wording, and the ambient temperature is -50° to 40°.

1) Carton box

2) Wooden-frame

3) Wooden case

4) According to customer requirements

5) we are all familar with different requirement on package,So we could accept any OEM service. Make your brand more famous than before.